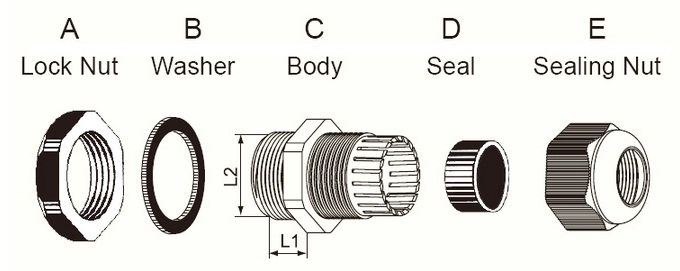

Material: Parts A, C, E are made of UL approved nylon

PA66, parts B and D are made of nitrile butadiene

rubber (NBR).

Thread spec.: Metric, PG, G, NPT.

Working temperature: -40℃ to 100℃ in static state,

instantaneous heat resistance up to 120℃; -20℃ to

80℃in dynamic state, instantaneous heat resistance up

to 100℃.

Characteristics: Special design of clamping die and

rubber part, large range in clamping cable, ultra-strong

stretching resistance, waterproof, dustproof, and high

ability to resist salt, acid, alkali, alcohol, grease and

general solvent.

Color: Black(RAL9005), light grey (RAL7035), silver

(RAL7001) as well as special colors that can be

designed at request.

CHEMICAL PROPERTIES. PA 66 resists most solvents. It is insoluble in esters, ketones, aromatic hydrocarbons, alkalis, dilute acid solutions and most organic acids. It has excellent resistance to oils and fats. Some chlorinated hydrocarbons cause swelling. PA 66 is attacked by strong acids or oxidizing agents. Formic acid and phenol are solvents. It is reversibly swollen by water which worsens the electrical properties, increases toughness and reduces stiffnes. PA 66 is affected by UV light leading to surface "chalking" or fading followed by embrittlement. Protection can be achieved with 2 to 3 % carbon black. On burning PA 66 melts, darkens, bubbles and then burns with a small blue flame with an orange edge. White smoke is emitted and the flame is easily extinguished giving off a celerylike odour. One way of classifying nylons is by melting point. PA 66 has a sharp melting point of 256 C compared to PA6 at 220 C. PA 66 is more resistant to chloroform, benzyl alcohol and trichloroethylene than PA 6. In addition PA6 will dissolve in 4N hydrochloric acid and boiling N,N-dimethylformamide while PA 66 will not. PA 66 sinks in water as it has a density of 1.14 g/cm3 and will float in saturated magnesium chloride solution. |